Quality made in Germany since 1928

JOMOS Comfort Engineering

We manufacture all JOMOS shoes on the principle of Comfort Engineering. As revealed by the name, our team has researched, developed, worked meticulously and optimised this for many years. Over the years we have adjusted our production steps in such a way that all shoes manufactured are all-round talents. Women’s shoes as well as men’s shoes combine a carefully thought-out interior with an insole concept which gently supports your feet when walking. Full-grain quality leather gives your favourite pair not only their fashionable style but also make possible the comfortable fit. The Air Comfort sole is light and flexible, it mutes your steps and guarantees an ergonomic rolling of your feet.

Shoe Construction

Shoe Lasts

Precision Last Technology

The precision shoe last robot ensures the popular fit of our shoes. It also shapes the form, character and appearance of every pair of shoes that leave our warehouse. In the constructing these lasts great precision is required as even a tenth of a millimetre counts. From this precision, there later results the comfortable wear that you can feel during strolling in town or on a walk.

Last Library

We keep the shoe lasts in a vast last “library” in our shoe factory in Selbitz. For every model and width for women’s sizes 36-44 to men’s 38-53 the matching lasts are ready for use in the production process.

As soon as a new model is developed the relevant last also find its place there.

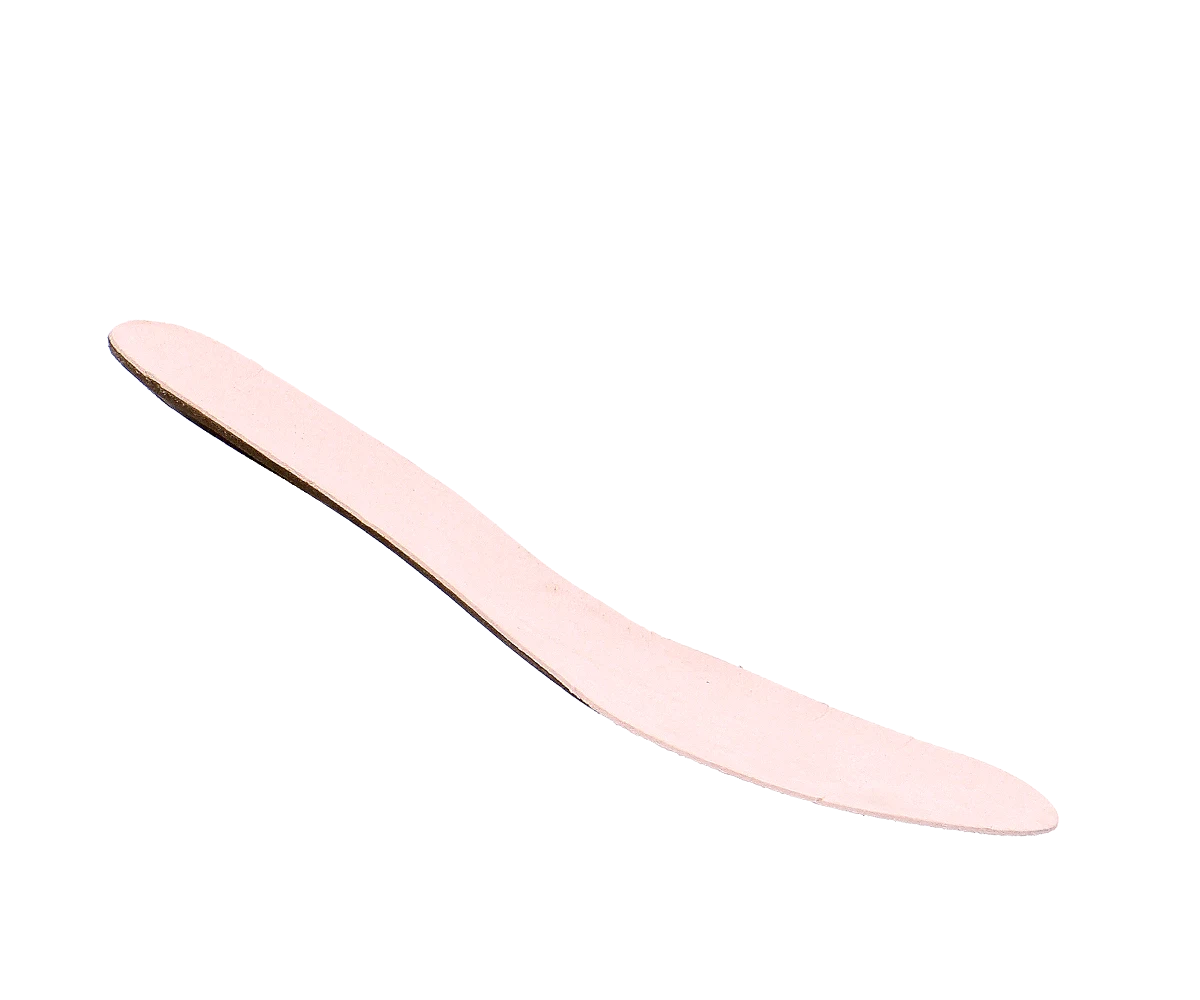

Inner Sole

From the outside, you see only the outer sole of your pair of JOMOS shoes as well. The removable insole is located in the inside of your shoe. Fitted between these two components is the inner sole.

In the course of production, our workers incorporate these in such a way that they can no longer be separated. In this way the shoe holds together from inside out. This stabilises the shoe – and your gait.

The JOMOS Insole Concept

A central component of every good shoe is its insole. You can exchange or renew the insole in every JOMOS shoe. So that you too can find the suitable insole for your feet we offer you seven differing variants:

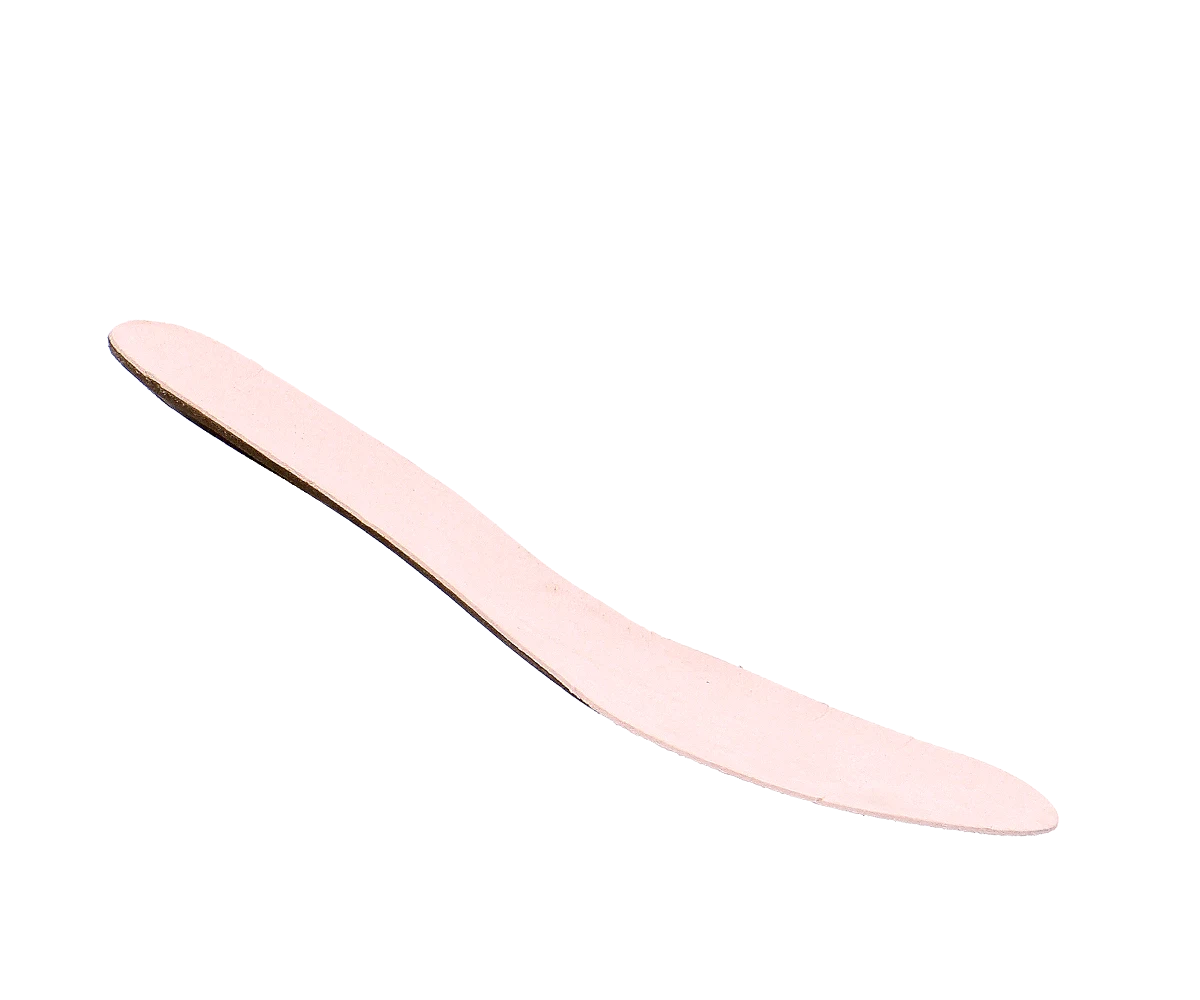

1. GreenCom Removable Insole

Our luxury variant for special wearing comfort. Chrome-free tanned natural leather is combined here with an impact-absorbing latex foam on the underside. Through which the GreenCom removable insole has excellent breathability and is kind to the skin.

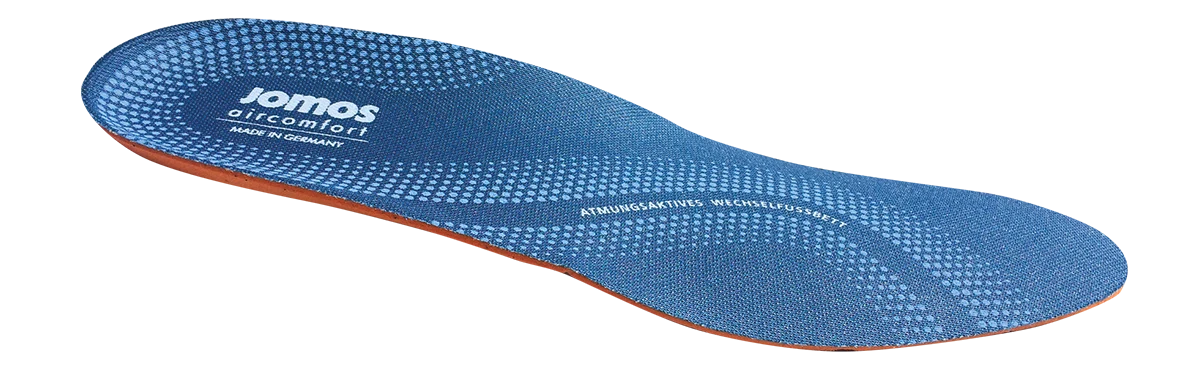

2. AirBlueCom Removable Insole

On a shape-retaining soft foam basis it fits your foot perfectly. A textile surface ensures not only for comfortable wearability but also for an always comfortable shoe climate.

3. AirCom Removable Insole

An everyday insole of soft foam cushioning and a surface in a suede look which is very breathable and which absorbs moisture in the shoe. For comfortable wearability and a balanced shoe climate AirCom is your convenient companion.

4. Leather Cushion Removable Insole

Ultra-soft insole with high-quality suede covering for all JOMOS sandals.

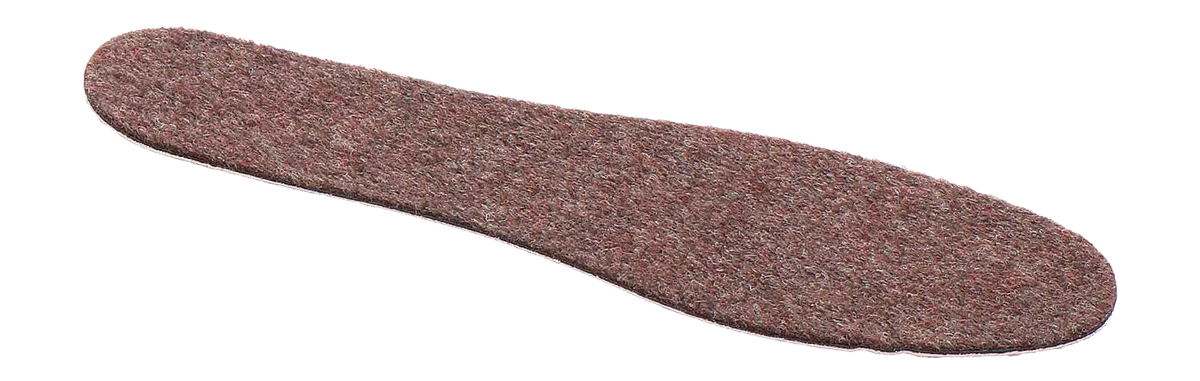

5. WollCom Removable Insert

We recommend this insole for the winter and against your cold feet. Through the underside of active charcoal carbon latex and the fleecy wool lining it is odour-absorbing and warming.

The JOMOS PU Sole

Aircomfort – made in Germany, which means: during the course of production in Selbitz the outer sole of polyurethane (PU) is injected direct on to every JOMOS upper. This results in a sole which gives a comfortable lightness to every pair through its own limited weight. In addition, the PU sole absorbs impact and thereby preserves your joints. Not least, the PU material is heat insulating outer which stands out in both the summer and the winter. Certainly, on these soles you will be happy to be out and about for longer.

Upper Leather

Our popular quality results from the use of high-quality materials. Thus, we use on the outside of the shoe soft, full-grained quality leather which is both fashionable and durable. So that this standard can remain in force we work closely together with our leather partners.

Interior of the Shoe

We also pay attention to the use of quality materials for the interiors of our JOMOS shoes. Here you can see a selection:

Bio Leather Lining

This very high-quality leather lining is chrome-free tanned – for very soft, comfortable wearing.

Leather Lining

We use only the best soft leather in our models with a leather lining.

Textile Lining

These models feature our tried and tested textile lining. High-quality, soft, and breathable.

Sympatex®

Sympatex® is known the world over for waterproof and breathable functional membranes from sustainable and resource-friendly production. We have been licensed to use these top lining materials and we are a market leader.

JoTex

These models also feature a waterproof and breathable functional membrane – suitable for all types of weather.

Real Lambskin

For generations the best choice for cold days and indispensable as lining for our most popular winter boots. Lambskin is naturally a perfect foot climate and is always pleasantly warming.

Warm Lining

You are ideally equipped for cold days with our models with the fluffy warm lining.